|

|

|

GAS DETECTION - HYDROCHLORIC ACID (HCl) |

|

|

|

|

|

|

|

Hydrochloric acid, HCl

Hydrochloric acid is a colourless, corrosive gas with a pungent

odour.

Hydrochloric acid is soluble in water and the solution is called

hydrochloric acid, this may be important to think about when the

leaking gas can result in corrosive concentrations of hydrochloric

acid, if it comes into contact with water.

HCL is obtained as a byproduct in the chemical industry and used in

particular in the semiconductor industry.

Hydrochloric acid is highly irritating to the eyes and mucous

membranes.

Odour threshold limit value is about 5 ppm.

If the concentration increases up to about 100 ppm it may give rise

to very serious pain.

Very high concentrations are associated with mortal danger.

Important to note is that the fact that symptoms may arise much

later.

Persons who have been exposed to HCl

should see their doctor immediately.

Threshold limit value for max. gas concentration is 5 ppm

Alarm limit should be set at the upper limit value.

Because the gas is readily absorbed by materials in the pipelines

etc., the use of aspiratory systems may be problematic.

Sensor Placement

Hydrochloric acid is slightly heavier than air which means that the

detectors should in most cases be placed low, since the gas will

sink to the floor.

In some cases, however, you cannot trust this fact.

Explosion Risk

Hydrochloric acid can, together with certain other substances to

cause explosions.

Examples of such substances are ammonia, ethylene oxide, and others.

References |

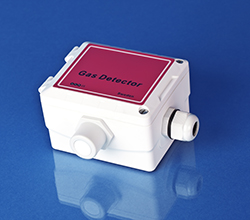

IP 65,

Wall design |

|

|

|

IP65,

Duct design |

|

|

|

|

ATEX Gas detectors are available for 2

explosion classes as follows:

Zone 1 is available with or without display .

Gas detectors for ATEX Zone 1 are located in a flameproof enclosure,

EEx d

The shell is such that ignition and

combustion within the shell of a potential explosive gas mixture is

not propagated to the explosive mixture outside the enclosure and

the enclosure can thus endure the resulting explosion pressure

without damage.

In Zone 1 ,

one can expect an explosive atmosphere to occur during normal

operation but the presence of it is relatively

short.

The equipment shall not be a source of

ignition in normal operation or when an error occurs.

Gas detectors for ATEX Zone 2 are of the

design Non-sparking EEx nA

EEx nA is a non-sparking piece

equipment.

In Zone 2, you need not count with an

explosive atmosphere to occur during normal operation, and if it

should occur, which is probably rare it is of

short duration.

The equipment shall not be a source of

ignition during normal operation.

|

|

|

|

|

|